Items

-

Howes Leather in Frank, Pocahontas County, WV. In addition to more efficient logging technologies, wood-byproduct industries—like paper and leather production—boosted profits for timber companies and hastened the depletion of forest resources. Commercial logging operations sold chestnut, oak, and hemlock bark to tanneries, which needed this tannin-rich byproduct to make leather. As industrialized logging made tree bark more available, the tanning of animal hides—once a small-scale trade in Appalachia—transitioned to a commercial industry. Although it reduced logging waste by providing a use for bark, leather tanning produced pollutants that contaminated nearby waterways. Additionally, the demand for tannins further incentivized the destruction of chestnut trees, even after a deadly blight began wiping them out.

Howes Leather in Frank, Pocahontas County, WV. In addition to more efficient logging technologies, wood-byproduct industries—like paper and leather production—boosted profits for timber companies and hastened the depletion of forest resources. Commercial logging operations sold chestnut, oak, and hemlock bark to tanneries, which needed this tannin-rich byproduct to make leather. As industrialized logging made tree bark more available, the tanning of animal hides—once a small-scale trade in Appalachia—transitioned to a commercial industry. Although it reduced logging waste by providing a use for bark, leather tanning produced pollutants that contaminated nearby waterways. Additionally, the demand for tannins further incentivized the destruction of chestnut trees, even after a deadly blight began wiping them out. -

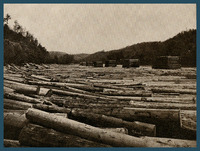

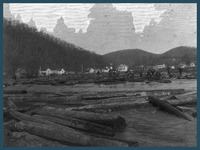

Log boom constructed by the St. Lawrence Boom and Manufacturing Company on the Greenbrier River, near Ronceverte, Greenbrier County, WV.

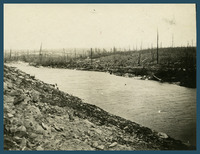

Splash dam on the Guyandotte River, Raleigh County, WV, 1907. During the dry summer months, logging companies constructed splash dams on streams. These dams held back water until stream levels were high enough to float logs. When the dam gates opened, the rushing water carried logs downstream. To help loggers direct and sort the floating timber, booms caught and held logs as they traveled downriver to sawmills. The booms consisted of two main parts: 1) “cribs” made from logs stacked in a square-shaped tower and anchored with huge rocks, and 2) “strings” of logs chained together to create a floating barrier and connect the cribs. According to one local historian, most boom companies in West Virginia “went up the creek into bankruptcy” once railroads replaced waterways as the principal way of moving logs to the mills.

Log boom constructed by the St. Lawrence Boom and Manufacturing Company on the Greenbrier River, near Ronceverte, Greenbrier County, WV.

Splash dam on the Guyandotte River, Raleigh County, WV, 1907. During the dry summer months, logging companies constructed splash dams on streams. These dams held back water until stream levels were high enough to float logs. When the dam gates opened, the rushing water carried logs downstream. To help loggers direct and sort the floating timber, booms caught and held logs as they traveled downriver to sawmills. The booms consisted of two main parts: 1) “cribs” made from logs stacked in a square-shaped tower and anchored with huge rocks, and 2) “strings” of logs chained together to create a floating barrier and connect the cribs. According to one local historian, most boom companies in West Virginia “went up the creek into bankruptcy” once railroads replaced waterways as the principal way of moving logs to the mills.

Railroad section crew in West Virginia.

Railroad section crew in West Virginia. Fourth Avenue, Marlinton, Pocahontas County, WV.

Fourth Avenue, Marlinton, Pocahontas County, WV. View of the Blackwater River near Davis, Tucker County, WV.

View of the Blackwater River near Davis, Tucker County, WV. Overhead skidder in Blackwater Canyon, Tucker County, WV.

Overhead skidder in Blackwater Canyon, Tucker County, WV. Log loader, West Virginia Spruce Lumber Company, Boyer, Pocahontas County, WV.

Log loader, West Virginia Spruce Lumber Company, Boyer, Pocahontas County, WV. Shay No. 2 locomotive, West Virginia Pulp and Paper Company, Cheat Mountain, WV.

Shay No. 2 locomotive, West Virginia Pulp and Paper Company, Cheat Mountain, WV. Log drive near Marlinton, WV.

Log drive near Marlinton, WV. A log skidding crew with horses, Hacker Valley, Webster County, WV.

A log skidding crew with horses, Hacker Valley, Webster County, WV. Loggers in West Virginia, Pardee and Curtin Lumber Company.

Loggers in West Virginia, Pardee and Curtin Lumber Company. A hand-colored wood engraving based on a David Hunter Strother drawing, Seneca Rocks, Pendleton County, WV.

A hand-colored wood engraving based on a David Hunter Strother drawing, Seneca Rocks, Pendleton County, WV. My Mountain Home, from the journal of Mahala Chapman Mace Gregory.

My Mountain Home, from the journal of Mahala Chapman Mace Gregory. West Virginians at a barn raising.

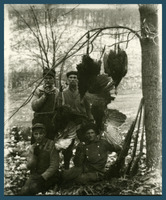

West Virginians at a barn raising. Turkey Hunting in Helvetia, Randolph County, WV.

Turkey Hunting in Helvetia, Randolph County, WV. Fishing from a log raft on the Cheat River at the mouth of Licking Creek, Tucker County, WV.

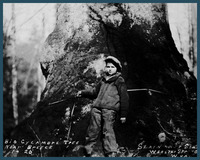

Fishing from a log raft on the Cheat River at the mouth of Licking Creek, Tucker County, WV. A giant sycamore tree near Webster Springs, Webster County, WV.

A giant sycamore tree near Webster Springs, Webster County, WV. Portable Sawmill and Crew in Preston County, WV.

Portable Sawmill and Crew in Preston County, WV. Mill Point, Pocahontas County, WV.

Mill Point, Pocahontas County, WV. A teamster and his horses dragging logs, Nicholas County, WV.

A teamster and his horses dragging logs, Nicholas County, WV. Loggers using a crosscut saw.

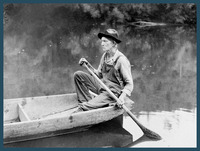

Loggers using a crosscut saw. A member of the Carpenter family paddling a hand-made canoe on the Elk River, Braxton County, WV.

A member of the Carpenter family paddling a hand-made canoe on the Elk River, Braxton County, WV. Arks accompanying a log drive on the Greenbrier River from Cass, Pocahontas County, to Ronceverte, Greenbrier County, WV.

Arks accompanying a log drive on the Greenbrier River from Cass, Pocahontas County, to Ronceverte, Greenbrier County, WV. Untitled [or Man Stands Among Cattle, All of Which Are Looking Straight at the Camera (WVHC title)]

Untitled [or Man Stands Among Cattle, All of Which Are Looking Straight at the Camera (WVHC title)] Three workers at a Sawmill in Montes, Randolph County, WV.

Three workers at a Sawmill in Montes, Randolph County, WV.